Stuttgart – For those managing a larger construction or agricultural vehicle fleet, it is a real headache knowing exactly where their vehicles are located, how long they have been operating. This is especially important at large and complicated construction sites, where not using these machines for the above-mentioned reasons can have negative effects in productivity. Bosch’s new, IoT-based connectivity asset tracing solution helps in utilizing machinery and other vehicles as efficient as possible at construction sites and farms, by allowing to continuously monitor the vehicles and analyze their location. “Bosch TRACI helps in keeping wait, search, and transportation times to a minimum,” says Jan Philipp Büchner, the product manager responsible for Bosch TRACI.

Vehicle utilization can easily be increased

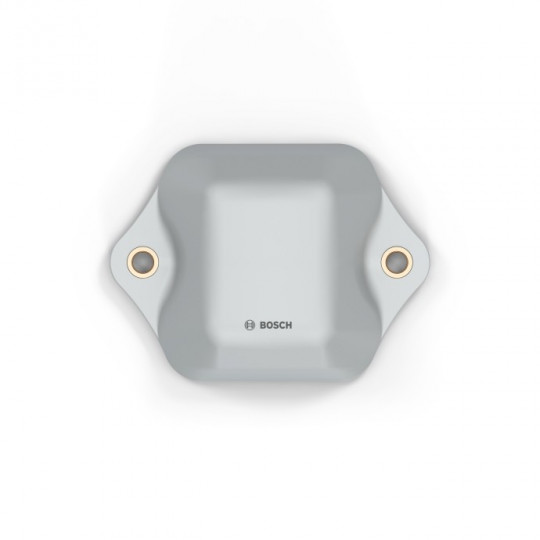

The solution comprises a sensor box, cloud-based evaluation software, and a wide array of digital services. Every vehicle is first equipped with a Bosch TRACI tag, a compact sensor box with its own power supply that captures the vehicle’s position, state of motion, as well as a lot of other data. The data is encrypted and transmitted via a LoRaWAN network to the Bosch IoT cloud, where it is decrypted. Customers and users can then access the sensor data, integrating it into their existing software systems for logistics, scheduling, and operations planning. Of course, the data can also be visualized directly on a smartphone app or in a web browser. With the help of Bosch TRACI, vehicles can be better utilized and the speed of distributing materials can also be increased.

Bosch’s asset tracing solution can also provide efficient help in agriculture: it dovetails with existing agricultural machinery systems as well as with the sensor-based monitoring solutions provided by the Bosch startup Deepfield. It can also be used to record the operating hours of coupled machines without an independent power supply (such as seeding machines). This can substantially lower the risk of breakdowns and expensive repairs.

Robust, long-lasting, versatile

During Bosch TRACI’s development, it was tested on construction sites and farm fields, to see if the sensors can withstand harsh conditions - such as being cleaned by high-pressure jets of stream. The device is also especially resistant to shock and liquids. In typical applications, the service life of a sensor is three to six years. That can be extended to ten years if the measurement and transmission intervals for sensor data are reduced.

The high levels of robustness and the long service life of Bosch’s solution also point to potential use cases in other markets besides the construction industry and agriculture. Deployed in smart-city scenarios, for instance, the sensors can make the management and tracing of local-government vehicles easier, or it can capture movements in infrastructure such as power pylons, enabling damage to be detected in good time. Bosch TRACI can also be a good solution in open-cut mines, where they can serve to check the condition of machinery and conveyor belts so that maintenance work can be performed as needed.

Zita Hella Varga

Phone: +36 70 667-6374

Mobility Solutions is the largest Bosch Group business sector. According to preliminary figures, it generated sales of 47 billion euros in 2018, and thus contributed roughly 60 percent of total sales from operations. This makes the Bosch Group one of the leading automotive suppliers. The Mobility Solutions business sector pursues a vision of mobility that is accident-free, emissions-free, and stress-free, and combines the group’s expertise in the domains of automation, electrification, and connectivity. For its customers, the outcome is integrated mobility solutions. The business sector’s main areas of activity are injection technology and powertrain peripherals for internal-combustion engines, diverse solutions for powertrain electrification, vehicle safety systems, driver-assistance and automated functions, technology for user-friendly infotainment as well as vehicle-to-vehicle and vehicle-to-infrastructure communication, repair-shop concepts, and technology and services for the automotive aftermarket. Bosch is synonymous with important automotive innovations, such as electronic engine management, the ESP anti-skid system, and common-rail diesel technology.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 410,000 associates worldwide (as of December 31, 2018). According to preliminary figures, the company generated sales from operations of 77.9 billion euros in 2018. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT company, Bosch offers innovative solutions for smart homes, smart cities, connected mobility, and connected manufacturing. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to deliver innovations for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 125 locations across the globe, Bosch employs some 69,500 associates in research and development.

Additional information is available online at www.bosch.hu, iot.boschblog.hu, www.bosch.com, www.iot.bosch.com, www.bosch-press.com, www.twitter.com/BoschPresse