Stuttgart, Germany – “A climate-neutral world won’t work without green hydrogen,” says Dr. Stefan Hartung, chairman of the Bosch board of management. Bosch is now expanding its business to include technology for water treatment. In addition to systems using the usual water treatment method of reverse osmosis, Bosch also plans to offer new solutions specifically engineered for remote areas and offshore locations. “Above all, the production of green hydrogen requires ultrapure water. With our special-purpose systems, water treatment can be done anywhere, even in the most remote areas of the world, in an economical and environmentally friendly way,” Hartung says. The systems designed by Bosch Manufacturing Solutions are not only robust and low maintenance, but compared to solutions commonly available on the market, they eliminate the need for chemicals in water treatment. “We’re developing technology for water treatment as well as for the generation, compression, storage, and use of hydrogen – and doing so for various sectors,” Hartung says.

Water treatment forms the first and most fundamental link in the hydrogen value chain. Bosch has developed the water treatment technology for electrolysis at its locations in Renningen, Stuttgart-Feuerbach, and České Budějovice, and external pilot projects are to be added in the course of this year. The market launch for the systems is planned for 2024.

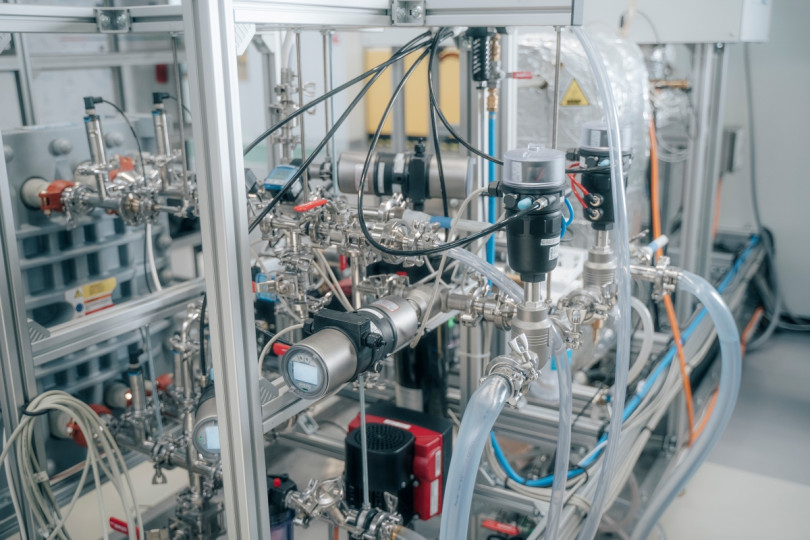

Special-purpose water treatment systems for the toughest conditions

Electrolyzers require ultrapure water for the production of hydrogen. “Impurities in the water can render electrolyzers inoperative in a very short time,” explains Dr. Wolfgang Schleifenbaum, head of the Hydrogen business unit at Bosch Manufacturing Solutions. In the future, hydrogen will be produced in areas with strong winds or abundant sunshine – Africa, South America, or Northern Europe, for example. Locations offshore or in the desert present particular challenges: considerable distances from the technical facilities, water high in salt or minerals – all make water treatment more difficult. As a result, demand for special equipment is high: Bosch expects that starting in 2035, some 500 of the company’s special-purpose water treatment systems will be needed worldwide each year.

The Bosch systems remove minerals from the water by means of thermal and electrochemical processes to obtain ultrapure water. Thanks to a treatment process without filter media, it is possible for operators to completely dispense with the use of chemicals. “Green hydrogen is sustainable only if its production doesn’t cause collateral damage to the environment; for example, by putting chemicals into our already heavily polluted waters,” Schleifenbaum explains. For predictive maintenance of the equipment, even from far away, Bosch offers software solutions that ensure robust operation in harsh environmental conditions.

Industrial systems for water treatment in developed areas

The demand for ultrapure water for the world’s hydrogen projects is enormous. As the world strives to achieve the Paris climate targets, Bosch estimates that, starting in 2050, annual demand for the water used in electrolysis will amount to some four cubic kilometers – more than the volume of Germany’s Lake Starnberg. The EU aims to install 40 gigawatts of electrolysis capacity in Europe by 2030, with plans to produce up to ten million metric tons of renewable hydrogen (source: European Commission, 2020). “Hydrogen will play a crucial role in the energy supply of the future. Industries worldwide must use hydrogen if they want to become climate neutral. Bosch supplies water treatment technology that meets different requirements with regard to the size, performance, and location of the electrolyzers,” Schleifenbaum says. For water treatment in developed areas, Bosch plans to expand its portfolio to include industrial systems that use reverse-osmosis processes and ion exchangers to turn tap water into the ultrapure water electrolyzers need.

Water treatment with Bosch technology – “Invented for life”

Bosch technologies also help maintain valuable drinking water reserves. The Bosch system is particularly efficient, reducing the feedwater required for producing water for the electrolysis process by up to one-third compared to common solutions on the market. In addition to producing water for electrolysis, the special-purpose systems can also be adapted to produce drinking water. “With our water treatment systems, we follow the Bosch guideline and offer technology that is ‘Invented for life.’ In areas where drinking water is scarce, we can use our technology to help improve the supply,” Schleifenbaum says.

Bosch Magyarország Podcast: about technology in a nutshell

The most abundant element in the known part of the universe will determine not only our energy storage and consumption patterns, but also our mobility in the coming decades. The latest episode of the Bosch Magyarország Podcast is about green hydrogen and its applications. The Bosch Magyarország Podcast is a quarterly show that covers the latest topics in innovation and R&D, with expert guests providing insightful answers to the most pressing questions about the technology of the future. To learn more about the future of the hydrogen economy, watch the show on Youtube or listen on the Bosch Magyarország Podcast channels: Spotify, Apple Podcasts, Google Podcasts and Simplecast!

Mónika Hack

+36 70 510 5516

The Bosch Group is a leading global supplier of technology and services. It employs roughly 421,000 associates worldwide (as of December 31, 2022). The company generated sales of 88.2 billion euros in 2022. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 136 locations across the globe, Bosch employs some 85,500 associates in research and development, of which nearly 44,000 are software engineers.

The company was set up in Stuttgart in 1886 by Robert Bosch (1861–1942) as “Workshop for Precision Mechanics and Electrical Engineering.” The special ownership structure of Robert Bosch GmbH guarantees the entrepreneurial freedom of the Bosch Group, making it possible for the company to plan over the long term and to undertake significant upfront investments in the safeguarding of its future. Ninety-four percent of the share capital of Robert Bosch GmbH is held by Robert Bosch Stiftung GmbH, a charitable foundation. The remaining shares are held by Robert Bosch GmbH and by a corporation owned by the Bosch family. The majority of voting rights are held by Robert Bosch Industrietreuhand KG, an industrial trust. The entrepreneurial ownership functions are carried out by the trust.

Additional information is available online at www.bosch.hu, iot.boschblog.hu, www.bosch.com, www.iot.bosch.com, www.bosch-press.com, www.twitter.com/BoschPresse