Stuttgart and Hannover, Germany – Industrial manufacturing is the engine of every economy. There is one major challenge that all manufacturers continue to face: to respond to climate change, factories must become sustainable and conserve resources. Bosch is one of the leading factory outfitters; its broad portfolio of solutions for factory automation, the hydrogen economy, digitalization, and artificial intelligence (AI) helps industrial companies achieve a green transformation.

Bosch industrial technology is in demand: in 2023, the supplier of technology and services was able to hold its own in a volatile market environment characterized by geopolitical tensions, the economic downturn, and interest-rate effects. Its sales of industrial technology rose to 7.4 billion euros. This equates to an increase of 6.8 percent, or 10.2 percent after adjusting for exchange-rate effects. The main drivers of this growth were Bosch’s acquisitions of HydraForce and Elmo Motion Control.

At Hannover Messe 2024, Bosch presented technologies and solutions in the fields of automation, digitalization, and hydrogen. “As an early adopter of artificial intelligence and digitalization applications, industrial technology is like almost no other sector,” said Tanja Rueckert, the member of the board of management of Robert Bosch GmbH responsible for the Industrial Technology business sector as well as the area of digital business and services. “Software and connectivity help increase efficiency, quality, and sustainability in production. The only way we can secure our standard of living and prosperity is with a strong industrial sector.”

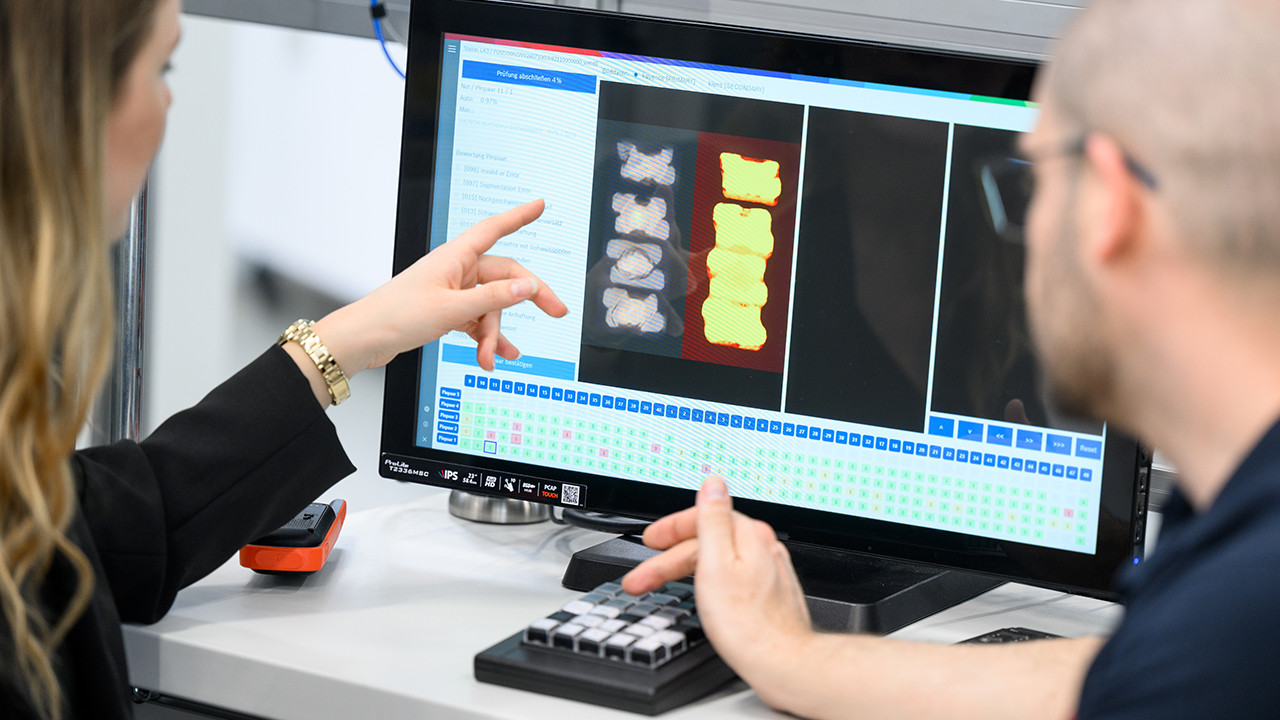

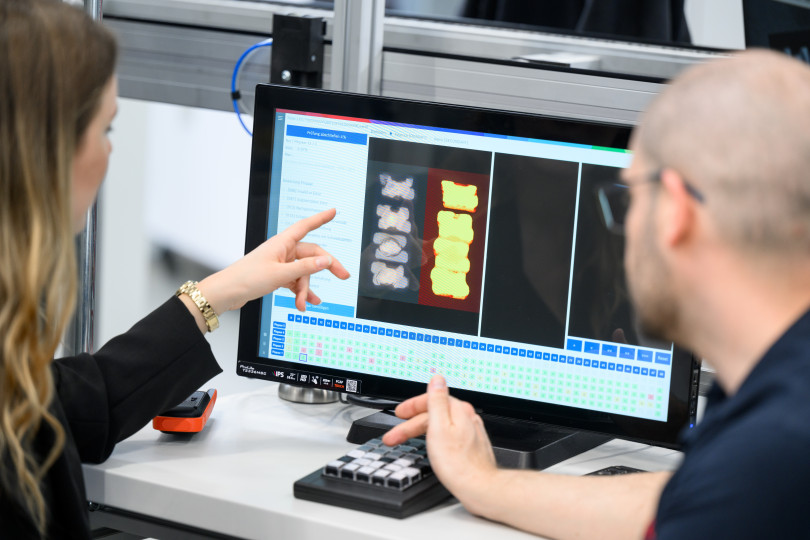

Generative AI: improve processes, increase quality

In manufacturing, Bosch wants to use generative AI to further improve production management, monitoring, and control. In two Bosch plants in Germany, the company has launched initial projects through which generative AI creates synthetic images in order to develop and scale AI solutions for optical inspection and to optimize existing AI models. Bosch expects that this will reduce the time needed for planning, launching, and ramping up AI applications from the current six-to-twelve months to just a few weeks. Developed by Bosch researchers, this service for generating synthetic data is to be offered to all Bosch locations following successful piloting.

ctrlX AUTOMATION: automation toolkit

The ctrlX AUTOMATION system for factory automation developed by Bosch Rexroth comprises hardware, software, and apps. It is an open platform that provides all the building blocks for complete automation solutions, and reduces component and engineering costs by 30 to 50 percent. The platform’s community of partners, known collectively as ctrlX World, is continuously expanding the range of solutions with hardware, and above all with apps. So far, 100 partners have contributed their strengths and solutions. Since its launch five years ago, the number of customers has risen to around 1,500. Sales in this area increased 30 percent in 2023.

Battery production: components for automated equipment

Whether in electromobility, consumer electronics, or building technology, the demand for energy storage is greater than ever. Bosch Rexroth offers a comprehensive portfolio for battery production that includes individual components, systems solutions, and subsystems featuring linear, joining, and transfer technology in addition to the fully open ctrlX AUTOMATION system. Speed and precision are also important in battery production. Bosch Rexroth has developed linear robots that can be used quickly for typical applications such as handling cells and packs as well as joining and dispensing. These robots optimize processes in module and pack assembly and disassembly.

Battery recycling: automation solution for deep discharge of batteries

There are more and more electric cars driving quietly and with low emissions on the roads. Their batteries contain rare and valuable raw materials such as lithium and nickel, the recovery of which makes economic and ecological sense. Bosch Rexroth’s toolkit solution for diagnosing, discharging, and dismantling used vehicle batteries enables the automation of these process steps, which are upstream of the actual process of recovering the raw materials. This makes it possible to recycle batteries on an industrial scale and offers the possibility of flexible scaling.

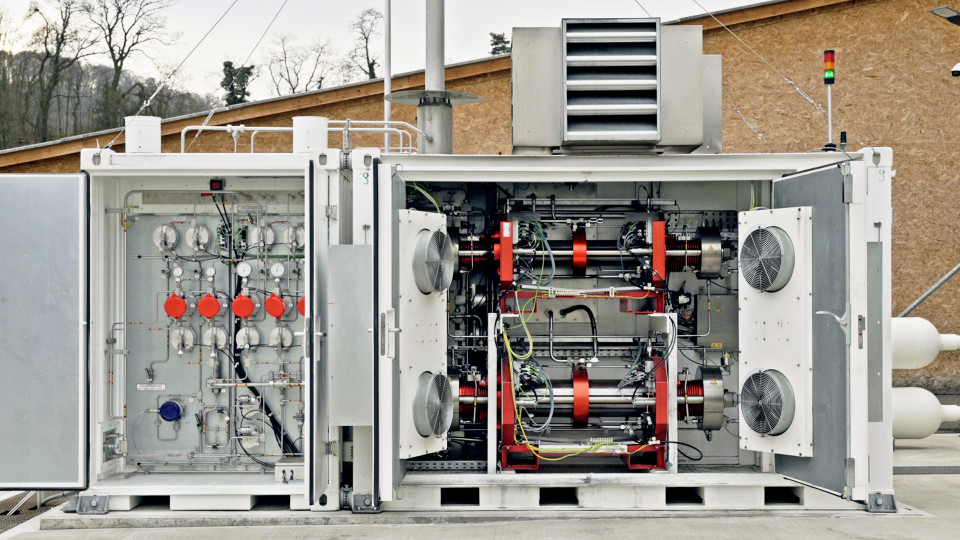

Hydrogen filling stations: drive solutions for compressing hydrogen

Hydrogen filling stations play a major role in decarbonizing the mobility sector. Within the next six years, several thousand hydrogen filling stations are set to go into operation worldwide. Together with partners, Bosch Rexroth has developed scalable solutions for servo-hydraulic compressor drives in the power range between 10 and 280 kW for the compression of hydrogen. To be able to refuel vehicles with hydrogen fuel quickly and simply, the gas has to be compressed to as much as 900 bar. A new electrohydraulically driven cryogenic pump has been developed in partnership with FirstElement Fuel, a leading company in the U.S. for the commercial operation of hydrogen filling stations. This cryogenic pump compresses liquid hydrogen directly to 875 bar. The aim is to refuel heavy trucks with 100 kg of hydrogen in under ten minutes. Direct refueling eliminates the need for intermediate storage tanks at filling stations. The first filling stations are set to be equipped starting in 2025. Moreover, Bosch Rexroth has worked with Maximator Hydrogen to develop scalable, low-maintenance drive units, with ratings currently up to 250 kW, that offer filling station operators an affordable way into hydrogen technology. The new container-based compressors can potentially reduce total cost of ownership by half compared with the commercially available alternatives. The Swiss Coop Group already uses hydrogen trucks for its goods transportation. They refuel at five filling stations equipped with Maximator and Bosch Rexroth technology.

Mónika Hack

+36 70 510 5516

The Bosch Group is a leading global supplier of technology and services. It employs roughly 429,000 associates worldwide (as of December 31, 2023). The company generated sales of 91.6 billion euros in 2023. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 90,000 associates in research and development, of which nearly 48,000 are software engineers.

The company was set up in Stuttgart in 1886 by Robert Bosch (1861–1942) as “Workshop for Precision Mechanics and Electrical Engineering.” The special ownership structure of Robert Bosch GmbH guarantees the entrepreneurial freedom of the Bosch Group, making it possible for the company to plan over the long term and to undertake significant upfront investments in the safeguarding of its future. Ninety-four percent of the share capital of Robert Bosch GmbH is held by Robert Bosch Stiftung GmbH, a charitable foundation. The remaining shares are held by Robert Bosch GmbH and by a corporation owned by the Bosch family. The majority of voting rights are held by Robert Bosch Industrietreuhand KG. It is entrusted with the task of safeguarding the company’s long-term existence and in particular its financial independence – in line with the mission handed down in the will of the company’s founder, Robert Bosch.

Additional information is available online at www.bosch.hu, iot.boschblog.hu, www.bosch.com, www.iot.bosch.com, www.bosch-press.com, www.twitter.com/BoschPresse