At Bosch, the “Connected Workshop”, its interaction with other web-based services and the application of Augmented Reality will be a key topic at Automechanika 2016. At the 2,400 m2 Bosch exhibition booth in hall 9, the connected workshop of the future can be experienced live between September 13 and 17, 2016. Several product presentations, taking place at the top of each hour, allow the visitors to get to know latest Bosch solutions in an interactive manner.

Intelligent data processing, the “Internet of Things” and increased networking of products with their environment bear a huge potential for automotive workshops. They ease the scheduling and planning of workshop appointments and improve the individual working steps in servicing. Vehicle data and the repair history are already available once the vehicle arrives at the workshop. The diagnostic equipment automatically exchanges data with one another and important manufacturer information can be accessed by the workshop professional in real time.

The connected workshop: Bosch Connected Repair

At Automechanika 2016, Bosch will first present its Connected Repair software. Connected Repair connects Bosch diagnostic equipment already available at the workshop. Without delay, once collected vehicle data is also made available to and on all other computer-based systems. In order to access the data of an already identified vehicle, the user just has to enter the respective vehicle’s license plate or the vehicle identification number (VIN) at the work station in use.

For subsequent workshop appointments, no additional identification is required. By means of the license plate or VIN, the complete vehicle history including all test results can be accessed at any work station and at any time. In addition, the software uses an innovative vehicle identification allowing the individual test devices to complement specific parameters. At a future appointment, these identification parameters are then used again. This saves set-up times at the individual work stations, eases the processes and prevents unnecessary duplication of work.

Using a photo feature, the vehicle condition can be documented by the workshop at a standardized and printable protocol. This allows informing the customers about necessary repairs in a transparent manner.

By means of an activation code, the software is activated for the connection of the whole workshop. It can then be used on any one of the workshop’s computers. For optimum performance, Bosch recommends to set up a separate server unit. Information on the vehicle’s life cycle can then be saved centrally and accessed at each individual work station if required. Using a standard interface, even the connection with most of the dealer-management systems is possible, too.

So far, the following Bosch systems can be connected using Bosch Connected Repair:

- ACS 752 air-conditioner service unit

- Esitronic 2.0 / KTS 5xx workshop-software package

- FWA 9000 and FWA 4630 wheel-alignment systems

- FSA 500 vehicle system analysis

By the end of 2016, the following systems will have been integrated as well:

- FSA 7xx vehicle system analysis

- HTD 815 headlight tester

- BEA 750 and BEA PC DE emission analyzer

Augmented Reality: Having an eye on key information at the right time

Additional information displayed by Augmented Reality is the key to an ever more sophisticated world of technology. It is increasingly difficult for automotive mechatronics to gain all required knowledge at everyday work and to apply it accordingly. Being able to access latest critical information at the right moment increases product understanding and saves time – the customers benefit from improved quality at repairs and the workshop from quicker processing.

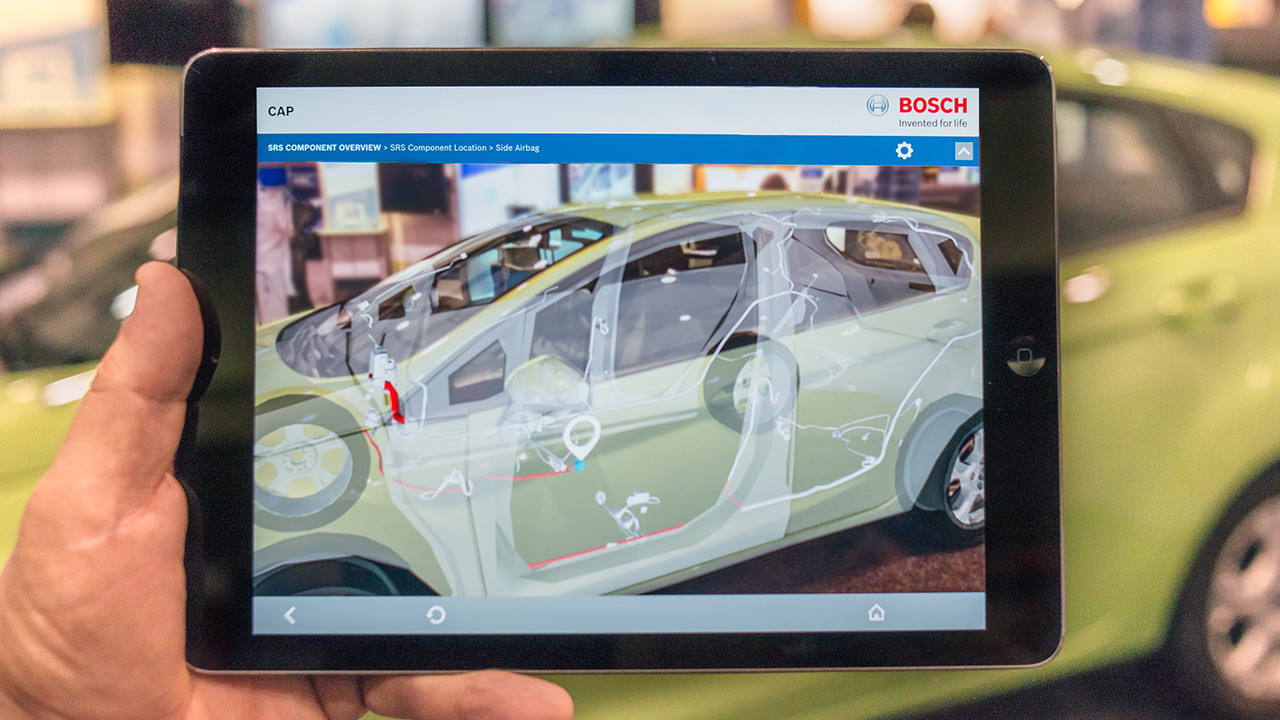

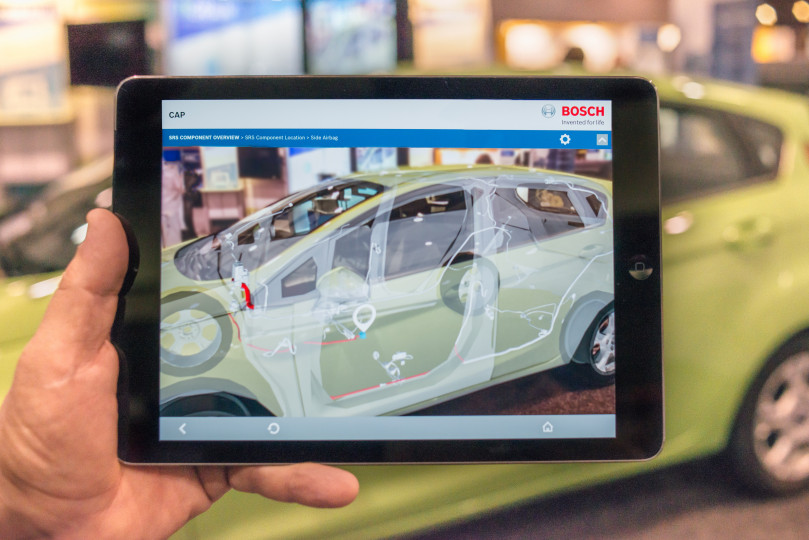

Pointing the device camera onto the vehicle, required additional information can be integrated into the real image using a tablet computer or smart glasses. This information can reach from explanatory texts and instructions, manuals or circuit diagrams, three-dimensional objects or photos down to videos. In this manner, even hidden components or cable harnesses can be displayed – a feature held in high regard by the mechatronics. The time required to perform sophisticated repair tasks can thus be reduced by 10 to 15 percent. Additional areas of application include apprenticeship, trainings and sales.

In order to create efficient Augmented Reality applications, Bosch created the Common Augmented Reality Platform (CAP) allowing the fast and easy integration of digital and visual contents, for instance into technical documentation. This cross-platform system works independently from specific tracking and rendering technologies. Bosch assumes that by 2018, the first workshops will already be working with such Augmented Reality applications.

Besides latest diagnostic equipment such as KTS 560 / 590 and the digital HTD 815 headlight tester, additional product highlights concerning the parts range will also include the M Li-ion motorcycle battery and the newly integrated product line Bosch steering systems. Furthermore, new connected telematics solutions for small and medium-sized businesses, which will be available for workshop customers, are presented as well.

Besides Bosch, the Beissbarth, Robinair, Sicam and OTC brands will also present their latest innovations.

Mónika Hack

+36 70 510 5516

The Automotive Aftermarket division (AA) provides the aftermarket and repair shops worldwide with a complete range of diagnostic and repair shop equipment and a wide range of spare parts – from new and exchange parts to repair solutions – for passenger cars and commercial vehicles. Its product portfolio includes products made as Bosch original equipment, as well as aftermarket products and services developed and manufac¬tured in-house. More than 18,000 associates in 150 countries, as well as a global logistics network, ensure that some 650,000 different spare parts reach customers quickly and on time. In its “Automotive Service Solutions” operations, AA supplies testing and repair-shop technology, diagnostic software, service training, and information services. In addition, the division is responsible for the “Bosch Service” repair-shop franchise, one of the world’s largest independent chains of repair-shops, with some 17,000 workshops. In addition, AA is responsible for more than 1,000 “AutoCrew” partners.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 375,000 associates worldwide (as of December 31, 2015). The company generated sales of 70.6 billion euros in 2015. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology.

The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiaries and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing and sales network covers some 150 countries. The basis for the company’s future growth is its innovative strength. Bosch employs 55,800 associates in research and development at 118 locations across the globe. The Bosch Group’s strategic objective is to deliver innovations for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.”

Additional information is available online at www.bosch.hu